1. Scrubber Systems

| Project Location | Industry | Capacity / Type | Remarks |

| Dahej, Gujarat | Chemical Plant | 50,000 CFM Spiral Scrubber | HDPR.Spiral type |

| Jhagadia | Agro chem | 20,000 CFM Dual-stage PPH Scrubber | Online acid mist control |

| Maharashtra | Dye Manufacturing | 2-Tower HDPE Scrubber | Tanks integrated with ducting |

2. Filtration Systems

| Client | Industry | Application | Type |

| Ankleshwar | Agro Chemicals | Solvent Purification | PPH Filter System |

| Rajasthan | Chemical | Cake Filtration | PPH Filter Unit |

| Gujarat | Intermediate | Cake Filter | HDPE Filter Unit |

3. Spiral Storage Tanks

| Capacity (Liters) | MOC | Use Case | Location |

| 80,000 Ltr | Spiral HDPE | Raw Material | Kutch, Gujarat |

| 50,000 Ltr | Spiral PP | Acid Storage | Dahej, Ahmedabad |

| 1,00,000 Ltr | Spiral HDPE | Storage Tanks | Gujarat |

4. Process Tanks & Vessels

| Client | Process | Capacity | Material |

| GIDC Vapi | Mixing Tank | 60 KL | Spiral HDPE |

| Ahmedabad | Neutralization | 25 KL | PP Spiral |

| Rajkot | Chemical Reaction | 50 KL | HDPE |

5. FRP & Rubber Lining Jobs

| Location | Surface Area | Type of Lining | Application Area |

| Jhagadia | 4000 sq. ft. | FRP Lining | Tank Internal |

| Dahej | 2500 sq. ft. | Rubber Lining | Acid Process Pit |

| Vatva | 1000 sq. ft. | FRP + Rubber Combo | ETP Channels |

6. Spiral Ducting Installation

| Industry | CFM | Material | Highlights |

| Textile, Surat | 50,000 CFM | Spiral HDPE | UV-stabilized outdoor routing |

| Pharma, Ankleshwar | 15,000 CFM | Spiral PP | Flame-retardant Grade Ducting |

7. Piping Projects

| Industry | Size Range | Length | Type |

| ETP Plant, Dahej | 63mm to 600mm OD | 800+ meters | HDPE Piping |

| Chemical, Vapi | 90mm to 315mm | 600+ meters | PP-H Piping |

Industries Served

About Us – Sumit Enterprise

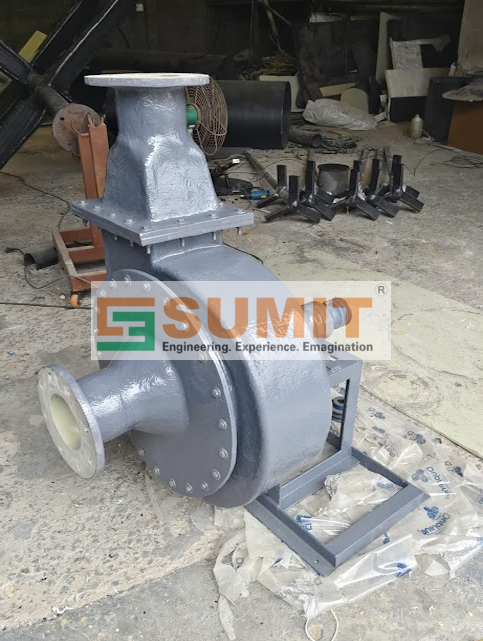

Founded in 2013, Sumit Enterprise is a trusted and innovative manufacturer and exporter of chemical processing equipment made from high-performance thermoplastics like HDPE, PP, and Spiral HDPE/PP. Headquartered in Ahmedabad, Gujarat, we specialize in designing and fabricating corrosion-resistant, leak-proof, and high-capacity equipment tailored for aggressive industrial environments.

Infrastructure & Team

- Dedicated 10,000 sq. ft. manufacturing unit with skilled technicians

- Advanced machinery for spiral tank winding, thermoplastic welding, and pressure testing.

- In-house design & QA team to ensure safety and compliance

- 12+ experienced engineers and staff at our India office

- Planned expansion in Texas (USA) to serve international clients

Why Choose Us Worldwide?

- 20+ Years of Industry Experience

- High Chemical Resistance and Long Life Equipment

- 100% Custom-Built Solutions as per Client Process

- Quick Turnaround, On-Site Support & Installation

- Commitment to Safety, Reliability, and Innovation

Let’s Build Something Durable Together.

Whether you’re storing corrosive chemicals or need robust ducting for emissions, Sumit Enterprise has the solution — engineered to perform, built to last.